Links:

-

Secondly, the complexity of the bearing's design impacts the price. Cylindrical roller bearings can be single row, double row, or even multi-row, each with varying load-bearing capabilities and operational characteristics. More intricate designs typically command a higher price due to increased manufacturing complexity and precision required. Manufacturing Process of Cylindrical Roller Bearings In addition to its performance characteristics, the D-5 thrust ball bearing is also known for its ease of installation and maintenance. This makes it a popular choice for manufacturers looking to reduce downtime and increase productivity. The D-5 thrust ball bearing is available in a wide range of sizes and configurations, making it suitable for a variety of applications.

- Proper Handling: When handling angular contact bearings, it's im * Pumps and compressors The impact of the 33895 bearing on the mechanical engineering industry has been profound. Its superior performance and reliability have led to a significant reduction in maintenance costs and downtime, resulting in increased productivity and profitability for businesses. Furthermore, its energy-saving properties have contributed to the development of more sustainable and environmentally friendly machines and systems.

- Spherical Roller Bearings: Spherical roller bearings are well-suited for applications where misalignment, heavy radial loads, and moderate axial loads are present. Their ability to accommodate misalignment makes them valuable in applications where shaft deflection or housing misalignment may occur.

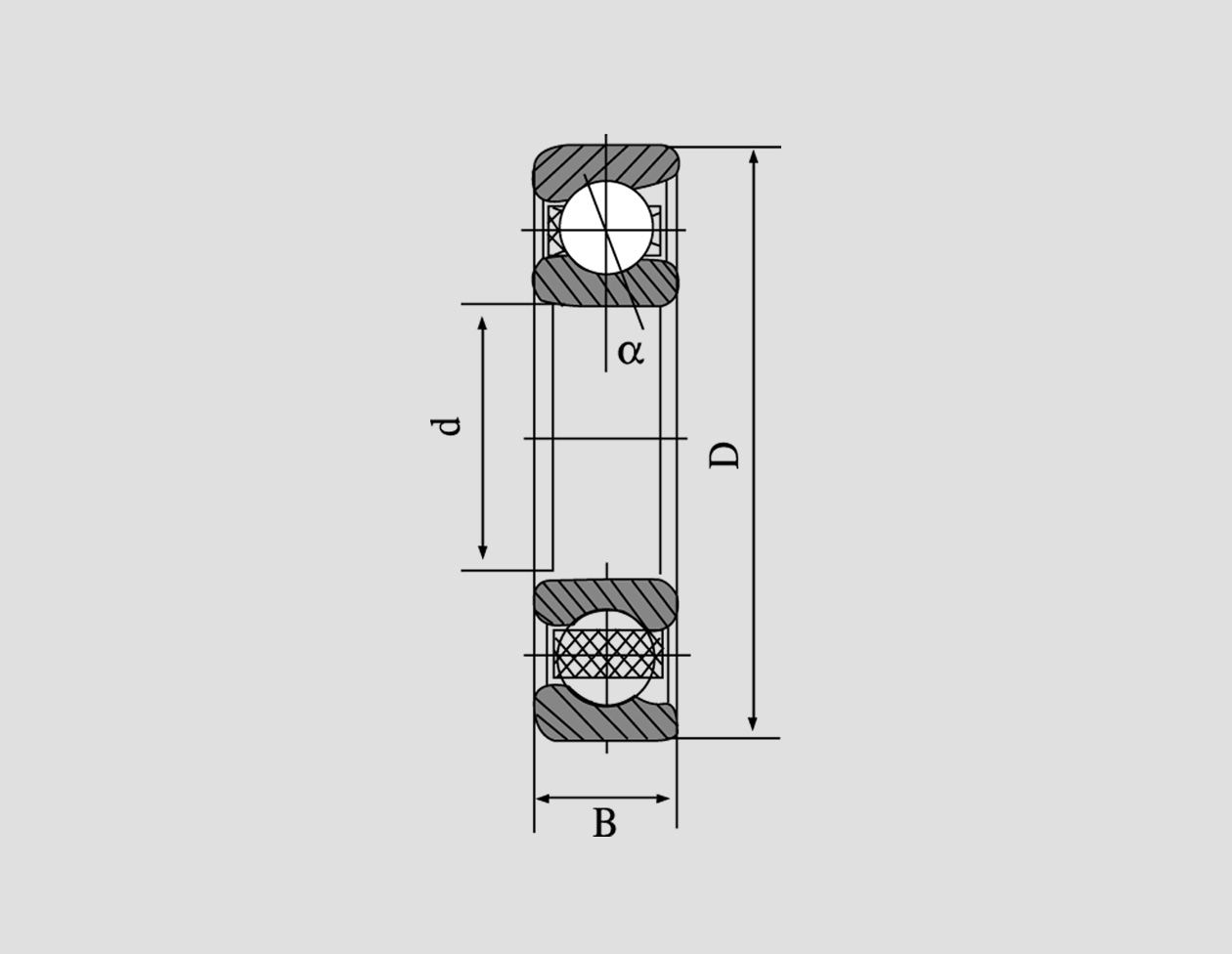

Understanding the Importance of Bearing Dimensions Another significant advantage of these bearings is their high load capacity. The wedge shape of the bearing generates a large contact area, which distributes the load evenly across the surface. This results in higher load carrying capacity and longer bearing life, even under heavy loads. The structure of a deep groove ball bearing is relatively simple yet highly efficient. It typically consists of an inner ring, an outer ring, a cage (or separator) to maintain the position of the balls, and a set of high-precision balls. The deep grooves serve as tracks for the balls, ensuring they maintain contact with both rings simultaneously, thus enabling the bearing to support both radial and axial loads. The LM67010 bearing is specifically designed to handle high speeds and loads, making it an ideal solution for applications that demand precision and durability. Its unique design features, including a double-row angular contact ball bearing, provide superior stability and support, allowing for optimal performance even under extreme conditions. Development of 24052 Bearings When selecting ball bearings for a specific application, it is essential to consider the expected thrust load that will be exerted on the bearings. This involves calculating both the static and dynamic thrust loads, which are the maximum and fluctuating thrust loads experienced by the bearings, respectively. Manufacturers provide load ratings for their ball bearings, which indicate the maximum thrust load that the bearings can safely withstand under ideal operating conditions. 3 In the realm of precision engineering and mechanical systems, the role of bearings cannot be overstated. Among the myriad of bearing types, the 62001 2RS bearing stands out as a crucial component in various applications due to its unique features and performance capabilities. This particular bearing, with its RS designation, denotes a rubber seals inclusion, enhancing its functionality and durability. Proper lubrication is crucial for the longevity and performance of the 6309 bearing. The bearing is designed to operate effectively with a variety of lubricants, including grease and oil. It is recommended to use a high-quality lubricant that is compatible with the bearing material and operating conditions. Regular maintenance, including cleaning and re-lubrication, is also essential to prevent premature wear and failure. When shopping for a 22324 bearing, buyers should compare prices from multiple suppliers to ensure they are getting a competitive deal. Online marketplaces and industrial supply websites are good places to start, as they often have a wide selection of bearings from different manufacturers. Buyers can also contact manufacturers directly to request quotes and compare pricing. The Ball Bearing 6004 2RS is a high-quality, reliable bearing that offers excellent performance in a wide range of applications. Its sealed design, high speed capability, and precision manufacturing make it an ideal choice for various mechanical systems. If you're looking for a reliable and durable bearing for your application, the Ball Bearing 6004 2RS should be at the top of your list. The contact angle also affects the bearing's dynamic characteristics. A larger contact angle results in higher stiffness and better stability under heavy loads, while a smaller contact angle provides lower friction and higher speed capabilities. By carefully selecting the contact angle, engineers can optimize the performance of deep groove ball bearings for specific applications. * Maintenance-free Since the bearing is sealed, it requires minimal maintenance, saving you time and money in the long run. One of the key advantages of tapered thrust bearings is their ability to accommodate misalignment. This is particularly useful in applications where the shaft may experience slight misalignment due to manufacturing tolerances or thermal expansion. By allowing for some movement, tapered bearings can maintain stability and reduce wear on other components. In terms of materials, cylindrical roller bearings can be made from a variety of substances including high carbon chrome steel for standard applications, stainless steel for corrosion resistance, and ceramic materials for high-speed or high-temperature environments. Each material choice impacts the bearing's performance characteristics, such as its durability, speed capability, and resistance to environmental factors. Overall, the 6310zz bearing dimensions play a crucial role in its performance and suitability for different applications. Whether it is in automotive, agriculture, mining, or construction, this type of bearing provides the necessary support and durability to ensure efficient operation. With its high-quality construction and metal shields, the 6310zz bearing is a reliable choice for industries looking for a durable and high-performance bearing solution.- They have raceways that are parallel to the bearing axis, allowing them to effectively support radial loads and provide smooth and efficient rotation of shafts and components.

Benefits of Using the 23268 Bearing Bearing, NJ, is known for its annual cultural events that bring the community together Deep groove ball bearings like the 6206 Z are designed to handle both radial and axial loads, making them suitable for a wide range of applications. They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines

Deep groove ball bearings like the 6206 Z are designed to handle both radial and axial loads, making them suitable for a wide range of applications. They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines

They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines They are commonly found in motorcycles, pumps, fans, conveyors, and even in home appliances like washing machines 6206 z bearing. Their ability to operate at high speeds with low noise and vibration makes them a preferred choice in many industries. One of the key advantages of sealed cylindrical roller bearings is their ability to maintain lubrication and protect against contaminants. The sealed design prevents dust, dirt, and moisture from entering the bearing, ensuring smooth operation and extending the service life of the equipment. This feature is particularly beneficial in harsh environments where exposure to debris or liquids could compromise the performance of the bearing. Applications of 22211 k Bearing Understanding Tapered Roller Bearings ID 80, OD 140 In conclusion, the Bearing 6001 Z, with its compact size, shielded design, and versatile functionality, is a key component in modern machinery. It not only enables efficient operations but also contributes significantly to the overall durability and performance of the systems it is integrated into. As technology continues to advance, the significance of this humble yet essential bearing will likely only grow. Overall, the 6909 bearing is a versatile and reliable component that offers excellent performance in a wide range of industrial applications. Its high quality, compact design, low friction properties, and ease of maintenance make it an ideal choice for businesses that require reliable and efficient equipment. Whether you're running a small business or a large corporation, the 6909 bearing is sure to meet your needs and exceed your expectations. In the aerospace industry, where weight and space are at a premium, 6002 ball bearings are used in critical components such as landing gear and flight control systems. Their ability to withstand extreme conditions, including high speeds and temperatures, is essential for the safe operation of aircraft.

6206 z bearing. Their ability to operate at high speeds with low noise and vibration makes them a preferred choice in many industries. One of the key advantages of sealed cylindrical roller bearings is their ability to maintain lubrication and protect against contaminants. The sealed design prevents dust, dirt, and moisture from entering the bearing, ensuring smooth operation and extending the service life of the equipment. This feature is particularly beneficial in harsh environments where exposure to debris or liquids could compromise the performance of the bearing. Applications of 22211 k Bearing Understanding Tapered Roller Bearings ID 80, OD 140 In conclusion, the Bearing 6001 Z, with its compact size, shielded design, and versatile functionality, is a key component in modern machinery. It not only enables efficient operations but also contributes significantly to the overall durability and performance of the systems it is integrated into. As technology continues to advance, the significance of this humble yet essential bearing will likely only grow. Overall, the 6909 bearing is a versatile and reliable component that offers excellent performance in a wide range of industrial applications. Its high quality, compact design, low friction properties, and ease of maintenance make it an ideal choice for businesses that require reliable and efficient equipment. Whether you're running a small business or a large corporation, the 6909 bearing is sure to meet your needs and exceed your expectations. In the aerospace industry, where weight and space are at a premium, 6002 ball bearings are used in critical components such as landing gear and flight control systems. Their ability to withstand extreme conditions, including high speeds and temperatures, is essential for the safe operation of aircraft. - Cylindrical Roller Bearings: Cylindrical roller bearings consist of cylindrical rollers held in place by inner and outer rings, with the rollers positioned parallel to the axis of the bearing. They are designed to primarily support radial loads and provide high rigidity and precision.

cylindrical roller bearing suppliers. Mining These bearings are used in crushers, screens, and conveyors in mining operations. Introduction When it comes to axial load capacity, deep groove bearings are available in various sizes and configurations to meet the specific requirements of different applications The inner diameter of the 6014 bearing is 70mm. This dimension determines the size of the shaft that can be inserted into the bearing. It is important to ensure that the ID of the bearing is compatible with the shaft diameter to prevent damage to either component. One of the key advantages of cylindrical roller bearings is their ability to accommodate both radial and axial loads. This makes them suitable for use in applications where the shaft has significant misalignment or where there is a combination of radial and axial forces acting on the bearing. The rollers are designed to distribute the load evenly across the bearing surface, which helps to reduce friction and wear. As the demand for more efficient and precise machinery grew, so did the demand for bearings that could withstand even greater stresses

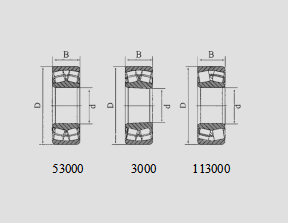

cylindrical roller bearing suppliers. Mining These bearings are used in crushers, screens, and conveyors in mining operations. Introduction When it comes to axial load capacity, deep groove bearings are available in various sizes and configurations to meet the specific requirements of different applications The inner diameter of the 6014 bearing is 70mm. This dimension determines the size of the shaft that can be inserted into the bearing. It is important to ensure that the ID of the bearing is compatible with the shaft diameter to prevent damage to either component. One of the key advantages of cylindrical roller bearings is their ability to accommodate both radial and axial loads. This makes them suitable for use in applications where the shaft has significant misalignment or where there is a combination of radial and axial forces acting on the bearing. The rollers are designed to distribute the load evenly across the bearing surface, which helps to reduce friction and wear. As the demand for more efficient and precise machinery grew, so did the demand for bearings that could withstand even greater stresses 6308 zz bearing. The 6308 ZZ bearing was soon modified to include features like improved seals, higher precision races, and optimized ball shapes. These enhancements not only increased the bearing's load capacity but also reduced noise and vibration, making it suitable for use in high-precision applications such as robotics and aerospace. Deep Groove Ball Bearings, a fundamental component in various mechanical systems, are a type of rolling-element bearing that primarily facilitate linear or rotational motion with minimal friction. These bearings, as their name suggests, feature deep grooves on the inner and outer rings, designed to accommodate balls that roll smoothly between them, thereby distributing loads evenly and reducing wear. 3. Sealing The 6302RS bearing features a rubber seal on both sides, effectively preventing contaminants from entering the bearing and extending its service life. The seals also prevent the loss of lubricant, ensuring optimal performance even in harsh environments. In conclusion, the taper bearing number is a critical piece of information that is essential for selecting the right bearing for a specific application. By paying attention to the taper bearing number and choosing high-quality bearings from reputable manufacturers, you can ensure reliable performance and long service life for your equipment. Remember to also provide regular maintenance and proper installation to keep your taper bearings in top condition. In conclusion, SRDG ball bearings are more than just mechanical parts; they are technological marvels that drive progress in various industries. Their importance cannot be overstated, as they facilitate efficient operations, improve performance, and extend the lifespan of equipment. As technology continues to evolve, the significance of SRDG ball bearings in ensuring precision, durability, and performance will only continue to grow. Understanding Angular Contact Ball Bearings A Guide to Size Charts

6308 zz bearing. The 6308 ZZ bearing was soon modified to include features like improved seals, higher precision races, and optimized ball shapes. These enhancements not only increased the bearing's load capacity but also reduced noise and vibration, making it suitable for use in high-precision applications such as robotics and aerospace. Deep Groove Ball Bearings, a fundamental component in various mechanical systems, are a type of rolling-element bearing that primarily facilitate linear or rotational motion with minimal friction. These bearings, as their name suggests, feature deep grooves on the inner and outer rings, designed to accommodate balls that roll smoothly between them, thereby distributing loads evenly and reducing wear. 3. Sealing The 6302RS bearing features a rubber seal on both sides, effectively preventing contaminants from entering the bearing and extending its service life. The seals also prevent the loss of lubricant, ensuring optimal performance even in harsh environments. In conclusion, the taper bearing number is a critical piece of information that is essential for selecting the right bearing for a specific application. By paying attention to the taper bearing number and choosing high-quality bearings from reputable manufacturers, you can ensure reliable performance and long service life for your equipment. Remember to also provide regular maintenance and proper installation to keep your taper bearings in top condition. In conclusion, SRDG ball bearings are more than just mechanical parts; they are technological marvels that drive progress in various industries. Their importance cannot be overstated, as they facilitate efficient operations, improve performance, and extend the lifespan of equipment. As technology continues to evolve, the significance of SRDG ball bearings in ensuring precision, durability, and performance will only continue to grow. Understanding Angular Contact Ball Bearings A Guide to Size Charts